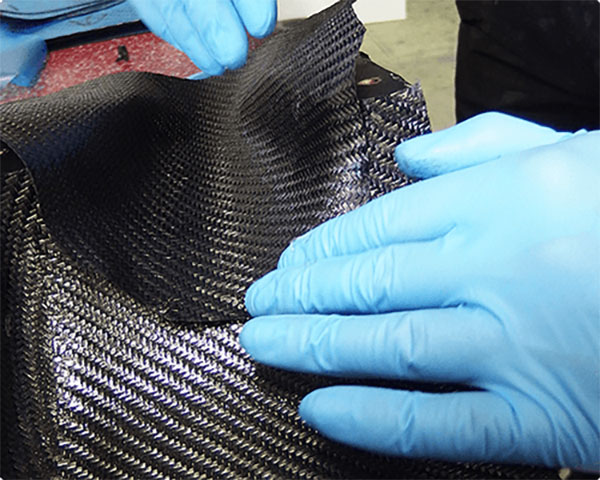

Peb muab cov khoom lag luam customized carbon fiber ntau.Tag nrho cov pa roj carbon fiber ntau qhov chaw thiab cov khoom lag luam yog tsim nrog cov khoom zoo epoxy prepreg.Peb feem ntau siv autoclave thiab qhov cub los kho cov khoom zoo.

Cov pa roj carbon fiber (CF) yog ib yam tshiab ntawm cov khoom siv fiber ntau nrog lub zog siab thiab siab modulus, uas muaj ntau dua 95% carbon.Nws yog tsim los ntawm flake graphite microcrystalline thiab lwm cov organic fibers stacked raws axial kev taw qhia ntawm cov fiber, thiab cov khoom siv microcrystalline graphite yog tau los ntawm carbonization thiab graphitization.Cov pa roj carbon fiber yog "mos rau sab nraud thiab nyuaj rau sab hauv".Nws qhov hnyav yog sib dua li ntawm aluminium, tab sis nws lub zog yog siab dua li ntawm cov hlau.Nws muaj cov yam ntxwv ntawm corrosion kuj thiab siab modulus.Nws yog cov khoom tseem ceeb hauv kev tiv thaiv hauv tebchaws, kev lag luam tub rog thiab kev tsim vaj tsev.Nws tsis tsuas yog muaj cov yam ntxwv ntawm cov khoom siv carbon, tab sis kuj muaj qhov softness thiab processability ntawm textile fiber, yog li nws yog ib tiam tshiab ntawm fiber ntau.

Dab tsi yog qhov ua haujlwm ntawm carbon fibers hauv kev sib xyaw?

Cov pa roj carbon fiber ntau muaj cov khoom muaj zog, siab modulus, kub tsis kam, corrosion kuj, qaug zog thiab creep tsis kam, hluav taws xob conductivity, thiab thermal conductivity.Nws yog tsuas yog siv rau kev npaj cov ntaub ntawv sib xyaw.

Kev Pab Cuam

■ Pwm ua

■ Npuag pretreatment

■ Composite curing

■ CNC machining

■ Lub rooj sib txoos

■ Thaum kawg glazing

Khoom Case

Kev Tsim Kho Tshuab

Pre-Preg hauv autoclave

muab cov khoom hnyav ultra-lub teeb uas muaj qhov zoo nkauj zoo nkauj.Pre-preg carbon fiber molding muaj kev siv hauv Formula One kev sib tw, nrog rau lwm tus.

Qhov cub curing

Resin infusion

zoo meej rau cov khoom loj ntawm cov qauv tsim qauv nrog rau cov rooj saum toj, casings, npog, nplooj ntawv.

Phau ntawv laminating

carbon fiber molding txoj kev siv rau cov khoom me me ntawm cov qauv tsim yooj yim uas tus nqi-zoo yog qhov tseem ceeb.

Cov peev txheej tsim khoom

Autoclave

Kev ua haujlwm siab tshaj plaws 8 bar, siab tshaj plaws kho qhov kub thiab txias 250 ° C - rau kev tsim cov khoom zoo carbon fiber ntau (pre-preg).

Autoclave #1: 3 x 6 m.

Autoclave #2: 0.6 x 8m.

Autoclave #3: 3.6 x 8m tuaj.

Qhov cub

Qhov cub - 4x2x2m, siab tshaj plaws kub: 220 ° C.

Hydraulic xovxwm

Cua sov daim hlau qhov ntev: 2000 x 3000 mm, siab 100 tons.

CNC machining chaw (3-axis)

Chaw ua haujlwm: X: 3000mm, Y: 1530mm, Z: 300mm.

Sander nrog txoj siv dav

Rau sanding nplooj ntawv mus rau qhov xav tau tuab, mus rau qhov tseeb ntawm 0.05 hli.

Txias Cia

Nws yog hais txog 30 ㎡ qhov twg pre-pregs khaws cia.

Chav tsev huv si

Peb chav huv huv muab ib puag ncig tsis muaj paug rau nteg cov ntaub ntawv sib xyaw, zoo tagnrho rau pre-peg lamination.

1000 square meter

1000 square meter ntawm qhov chaw tsim khoom.

Tshiab 5000 square meter yuav los sai sai no.

Digital X-Ray Tshuab

Rau kev soj ntsuam X-ray duab zoo ntawm cov khoom

Vim li cas Weadell?

■ Peb tau nruab nrog cov cuab yeej tsim khoom siab heev ntawm ntau yam kev qhia tshwj xeeb.

■ Peb siv cov txheej txheem ntau lawm kom tau raws li cov neeg siv khoom xav tau thiab cov kev xav tau.

■ Peb siv cov txheej txheem zoo tshaj plaws uas ua kom cov khoom zoo kawg nkaus nrog rau cov qauv tsim niaj hnub.

■ Peb muab cov kev pabcuam zoo tshaj plaws thiab cov khoom lag luam ua tsaug rau peb cov kws tshaj lij, cov kws tshaj lij tshwj xeeb, cov chaw niaj hnub thiab kev txhawb zog kom ib txwm muab qhov tshwj xeeb rau cov neeg siv khoom txaus siab.

Kev ua tiav qhov project

1. Kev sab laj

2. Tsim

3. Pwm thiab qauv

4. Qauv qauv

5. Batch Production

6. Tshuab

7. Kev sib txoos

8. Ua tiav

9. Kev Tswj Xyuas Zoo

10. Xa